Flame Resistant Conveyor Belt

Flame Resistant Conveyor Belt

- Product description:

Generation introduction:

The use of flame-resistant conveyor belts in coal mines is conducive to reducing the incidence of both above ground and underground fires. The working environment of coal mines is relatively complicated, coal dust and gas are dangerous factors, and the coal mines being transported are also flammable substances. If electric sparks are generated during transportation, it is easy to cause fires. The use of flame-resistant conveyor belts for coal mines reduces the possibility of electrostatic sparks during coal transportation, and even if static sparks occur, the flame-resistant conveyor belts for coal mines have high flame resistance and will not catch fire.

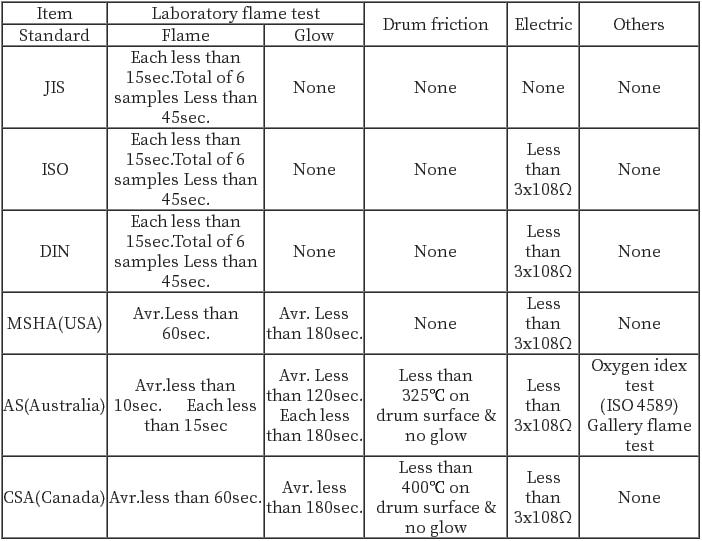

Test standard:

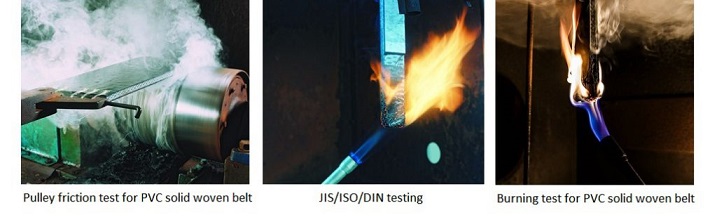

JIS/ISO/DIN tests involve exposing six individual samples of a belt to a naked flame causing them to burn. The source of the flame is then removed and the combustion time (duration of flame) of the test piece is recorded. A current of air is then applied to the test piece for a specified time after the removal of the flame. The flame should not reignite. The time it takes for the belt sample to self-extinguish after the source of ignition (flame) has been removed is then measured. The duration of continued burning (visible flame) should be less than 15 sec. for each sample with an absolute maximum cumulative duration of 45 sec.

Pulley friction test is the single biggest difference in the safety classifications (standards) between belting used above ground and belting used underground. If certification is required then these tests must be carried out by an independent test organization. The test standards demand that there should be no evidence of flame or glow during or after the test. This is only achievable by using a PVC belt because the thermoplastic melts/breaks before it reaches 325˚C, the SUNGDA maximum average is around 260 - 270˚C.

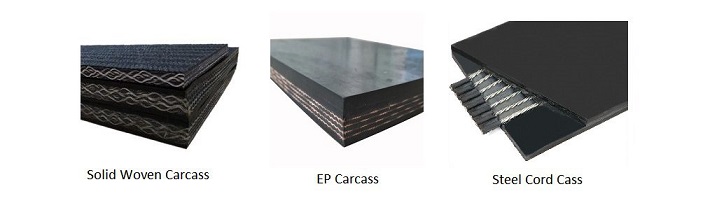

The flame-resistant management of coal mine flame-resistant conveyor belts must be done in the selection of conveyor belts, and the conveyor belts should be selected according to the different underground coal mine use conditions. At present, there are mainly three types of flame-resistant conveyor belts for coal mines: fabric layer flame-resistant conveyor belts, steel cord conveyor belts, solid woven conveyor belt. Among the three types of flame-resistant conveyor belts for coal mines, the first type of conveyor belt, that is, the fabric layer conveyor belt for coal mines is widely used, with a market share of more than 80%, has stronger flame retardancy, and has lower weight and cost.

Flame resistant test standards:

CATEGORIES

LATEST NEWS

- Which Country is The Best Choice for Purchasing Conveyor Bel2021-11-11

- What are the most commonly used areas of belt conveyors?2021-06-24

- Analyze the importance of flame-resistant conveyor belt from2021-06-10

- The most important index of rubber conveyor belt-----Tensile2021-06-09

- Carbon Black----One of the key factors affecting the quality2021-05-27

CONTACT US

Contact: Overseas Department

Phone:

Tel: +86-312-5308005

Email: info@sungdagroup.com

Add: Boye Rubber Industry Technical Development Park Baoding city, China